Specifications :

Material :Manganese steel wire

Wire diameter : 4-16mm(popular :6mm,8mm,10mm,12mm,14mm,16mm )

Aperture : 10-80mm

Hole shape : round , square or diamond

Edge : flat panel or hook bending .

Popular size :

| Wire Dia | Aperture | Wire Dia | Aperture | Wire Dia | Aperture |

| mm | mm | mm | mm | mm | mm |

| 6 | 10 | 11 | 26 | 13 | 50 |

| 8 | 10 | 28 | 60 | ||

| 12 | 30 | 14 | 45 | ||

| 14 | 32 | 50 | |||

| 16 | 35 | 55 | |||

| 20 | 12 | 28 | 60 | ||

| 9 | 20 | 30 | 65 | ||

| 22 | 32 | 70 | |||

| 10 | 20 | 35 | 75 | ||

| 22 | 38 | 80 | |||

| 25 | 40 |

|

|

||

| 28 | 45 |

|

|

*welding spot is strong , keep long -service life using .

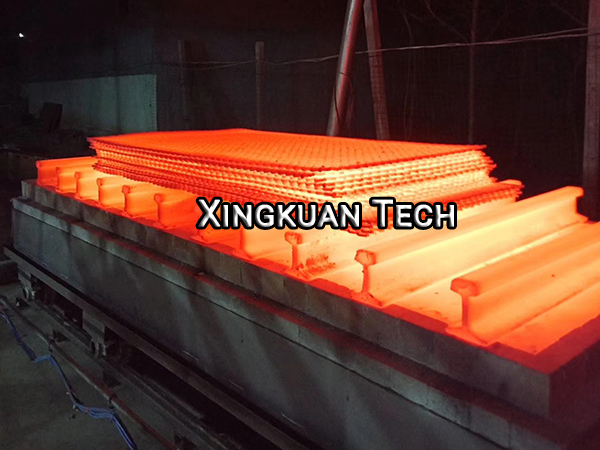

* high-temperature quenching and low-temperature tempering. It is not afraid of wear, not easy to corrode and has a long service time, which is 3-5 times that of ordinary screen

*hole shape can be round, square and diamond, which can be freely selected by customers

*When the old surface is worn, the new surface will form a wear-resistant layer, so it is mostly used in large coal mining industry.

*no surface treatment, convenient and simple maintenance,

*Low cost, good open area, and fast delivery.

Appications

It is mainly used in large stone processing, asphalt mixing station, coal mine, metallurgy, chemical industry and other industries( It can be used with various domestic and imported mechanical equipment). It is widely used in screening, filtration, dehydration, desliming and other operations in many industries

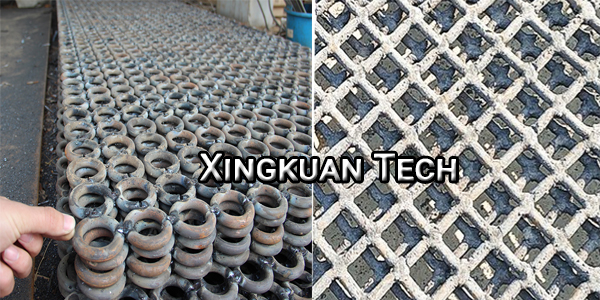

Different hole shape :

Reinfoced treatment: heating & quenching

Contact: Alisa Zhou

Phone: +86 18730291422

Tel: +86-311-68058665

Whatsapp: +86 18730291422

Email: info@wiremeshmadeinchina.com

Add: Room 2102 ,South building , intersection of Fuqiang Street and Huailing road ,Yuhua district ,shijiazhuang city ,hebei province

We chat